Máy nghiền hàm TENCAN EP60*95 Phòng thí nghiệm 1-5mm Đầu ra có thể điều chỉnh để nghiền đá/quặng/gốm

Thông tin chi tiết sản phẩm:

| Nguồn gốc: | Hồ Nam, Trung Quốc |

| Hàng hiệu: | TENCAN |

| Chứng nhận: | CE |

| Số mô hình: | EP60*95 |

Thanh toán:

| Số lượng đặt hàng tối thiểu: | 1 bộ |

|---|---|

| Giá bán: | USD 4380-4580 per set |

| chi tiết đóng gói: | Vỏ gỗ dán |

| Thời gian giao hàng: | 15-25 ngày làm việc sau khi nhận được thanh toán đầy đủ. |

| Điều khoản thanh toán: | T/T, Western Union |

| Khả năng cung cấp: | 200 bộ mỗi tháng |

|

Thông tin chi tiết |

|||

| Tên sản phẩm: | Lab Jaw Craser | Mô hình NO.: | EP60*95 |

|---|---|---|---|

| Điện áp: | 220V-50HZ | Sức mạnh: | 0,75KW |

| Kích thước nguồn cấp dữ liệu: | Ít hơn 35mm | Kích thước đầu ra: | 1,0-5,0mm |

| Công suất: | 10-50kg/giờ | Tốc độ trục chính: | 0-560 vòng / phút |

| Làm nổi bật: | Máy nghiền hàm phòng thí nghiệm 1-5mm,Máy nghiền hàm phòng thí nghiệm đầu ra có thể điều chỉnh,Máy nghiền hàm phòng thí nghiệm để nghiền gốm |

||

Mô tả sản phẩm

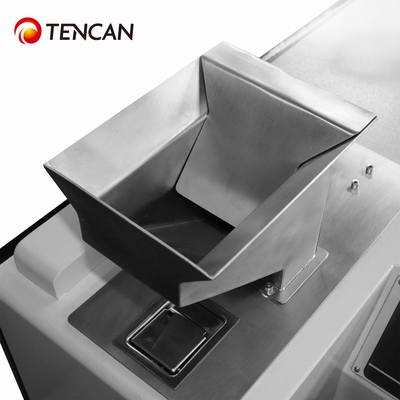

Máy Nghiền Hàm Phòng Thí Nghiệm TENCAN EP60*95 1-5mm Đầu Ra Có Thể Điều Chỉnh Để Nghiền Đá/Quặng/Gốm

Tổng quan về Máy Nghiền Hàm Phòng Thí Nghiệm

Máy nghiền hàm phòng thí nghiệm được thiết kế để nghiền sơ cấp hiệu quả các loại quặng và vật liệu rời khác nhau có cường độ nén dưới 320MPa. Máy nghiền hàm phòng thí nghiệm dòng PE của chúng tôi có nhiều thông số kỹ thuật toàn diện, phù hợp với kích thước nạp từ 125mm đến 1200mm, khiến chúng trở thành lựa chọn tối ưu để giảm kích thước ban đầu. Những máy móc mạnh mẽ này vượt trội trong việc xử lý các vật liệu bao gồm đá vôi, canxi cacbua, đá phiến sét, đá bazan, sỏi sông và các loại quặng khác nhau. Chúng thể hiện hiệu suất vượt trội trong nhiều ngành công nghiệp bao gồm sản xuất xi măng, khai thác mỏ, chế biến luyện kim và sản xuất vật liệu xây dựng, đóng vai trò là thiết bị không thể thiếu trong cả môi trường phòng thí nghiệm và công nghiệp.

![]()

Nguyên lý hoạt động của Máy Nghiền Hàm Phòng Thí Nghiệm

Ứng dụng của Máy Nghiền Hàm Phòng Thí Nghiệm

Máy nghiền hàm phòng thí nghiệm của chúng tôi được thiết kế đặc biệt để giảm kích thước sơ bộ các mẫu khoáng chất lớn và vật liệu rời trong môi trường nghiên cứu và kiểm soát chất lượng. Những máy này đặc biệt có giá trị trong các phòng thí nghiệm địa chất, cơ sở nghiên cứu khai thác mỏ và trung tâm thử nghiệm vật liệu, nơi việc chuẩn bị mẫu chính xác là rất quan trọng. Chúng xử lý hiệu quả nhiều loại vật liệu bao gồm quặng kim loại, cốt liệu xây dựng, khoáng sản công nghiệp và nguyên liệu gốm, tạo ra các hạt có kích thước đồng đều, lý tưởng cho các quy trình phân tích tiếp theo hoặc xử lý thêm trong máy nghiền bi và các thiết bị nghiền khác.

Tính năng của Máy Nghiền Hàm Phòng Thí Nghiệm

1. Hiệu suất nghiền vượt trội với tỷ lệ giảm lên đến 1:13, đảm bảo hiệu quả chuẩn bị mẫu tối ưu;

2. Cơ chế điều chỉnh được bảo vệ bằng miếng đệm tiên tiến cung cấp khả năng kiểm soát kích thước xả rộng và đáng tin cậy;

3. Thiết kế tiết kiệm năng lượng mang lại công suất xử lý cao hơn 20-35% trong khi giảm tiêu thụ điện năng từ 15-20% so với các mẫu thông thường;

4. Hình học buồng nghiền sâu được tối ưu hóa loại bỏ các vùng chết, tối đa hóa thông lượng và giảm thiểu mất mẫu;

5. Tấm hàm hyperboloid được thiết kế đặc biệt mang lại tuổi thọ cao hơn, đặc biệt khi xử lý các vật liệu có tính mài mòn cao;

6. Hệ thống bôi trơn tập trung đảm bảo hoạt động trơn tru đồng thời đơn giản hóa các quy trình bảo trì;

7. Kết cấu chắc chắn với các thành phần gia cố đảm bảo độ tin cậy lâu dài trong môi trường phòng thí nghiệm khắc nghiệt;

8. Thiết kế tập trung vào an toàn kết hợp nhiều tính năng bảo vệ để bảo vệ người vận hành trong quá trình vận hành.

Thông số kỹ thuật của Máy Nghiền Hàm Phòng Thí Nghiệm

| Thông số của Máy Nghiền Hàm Phòng Thí Nghiệm | |||||||

| Mã số | Công suất (Kg/h) | Kích thước cửa vào (mm) | Kích thước nạp (mm) | Kích thước đầu ra (mm) | Tốc độ trục chính (vòng/phút) | Nguồn điện | Khối lượng tịnh (KG) |

| XPC100*60 | 230-400 | 100*60 | ≤50 | 6.0-10.0 | 650 | 380V/1.5KW | 350 |

| XPC100*100 | 200-1800 | 100*100 | ≤80 | 3.0-25.0 | 600 | 380V/2.4KW | 300 |

| XPC125*100 | 200-1800 | 125*100 | ≤80 | 5.0-25.0 | 500 | 380V/3.0KW | 300 |

| XPC100*150 | 200-1800 | 100*150 | ≤90 | 6.0-38.0 | 500 | 380V/2.2KW | 360 |

| XPC150*125 | 400-3000 | 150*125 | ≤100 | 6.0-38.0 | 500 | 380V/3.0KW | 417 |

| PEF150*250 | 700-1500 | 150*250 | ≤120 | 6.0-40.0 | 350 | 380V/5.5KW | 500 |

| PEF60*100 | 45-550 | 60*100 | ≤50 | 1.0-10.0 | 290 | 380V/1.5KW | 110 |

| PEF100*100 | 65-850 | 100*100 | ≤80 | 1.0-25.0 | 600 | 380V/2.2KW | 320 |

| PEF100*125 | 300-2000 | 100*125 | ≤100 | 2.0-35.0 | 375 | 380V/3.0KW | 360 |

| PEF150*125 | 300-3000 | 150*125 | ≤120 | 4.0-45.0 | 375 | 380V/3.0KW | 380 |